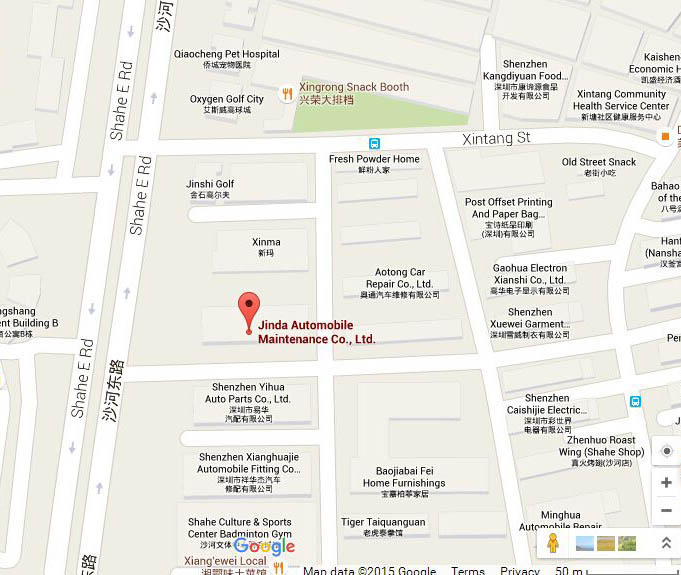

| Central Office | : | West of 3rd Floor, G5A Building, Shahe Industrial Zone , Shahe East Road Nanshan District, Shenzhen, China. Phone: +86-755-88363356 Fax: +86-755-22718885 |

| : | marketing@sanray.cn | |

| Web | : | www.sanrayrifd.com |

> Solutions > Production RFID Management System1.System overview:

The RFID technology application in the production management system can help the enterprise realize the production equipments operation surveillance, products going in or out of the warehouse management, and logistics distribution centre goods flowing management via RFID technology. Since there’s no need of visible reading and multiple-tag reading simultaneously features for RFID technology. Plenty of RFID tags with all the logistics data included can be read precisely at one time, which greatly improved work efficiency for the manufacturing enterprise on the “supply-production-logistics” supply chain process management. Supply process management: the RFID system can realize “Procurement control, orders matches, supply circle control, quality tracking, consigned processing control, on-the-way goods tracking”. Production process management: materials cost control, production statistics, piecework statistics. If required by the customers, RFID technology can also help realize the production line equipments parts operation surveillance management.

Logistics management: Distribution of goods as per orders, cooperation among multiple warehouses, warehouse receiving and sending goods, first-in-first-out, unloading alarming, statistics on the goods which don’t sell well, etc.

2. System characteristicsя╝Ъ

Realize “supply-production-logistics” integrated management

Enhance the production process work efficiency, realize the enterprise cost control management Effectively realize the goods logistics surveillance management Convenient, in-time and precise system data statistics